Nulogy Shop Floor Solution

Purpose-Built for High-Mix, Quick-Turn Manufacturing

You’ll often find it in operations with:

- Short runs and frequent changeovers

- Manual quality checks and downtime tracking

- Spreadsheets and whiteboards used for tracking

- Pressure to meet tight schedules and shifting demand

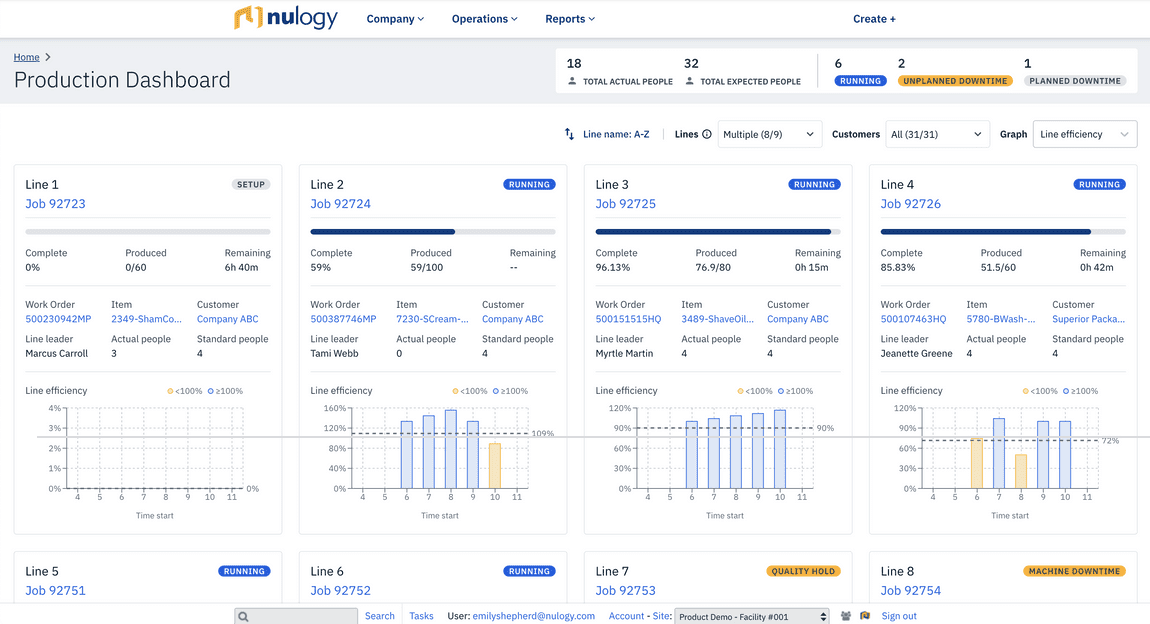

Stop Problems as They Happen with Real-Time Data

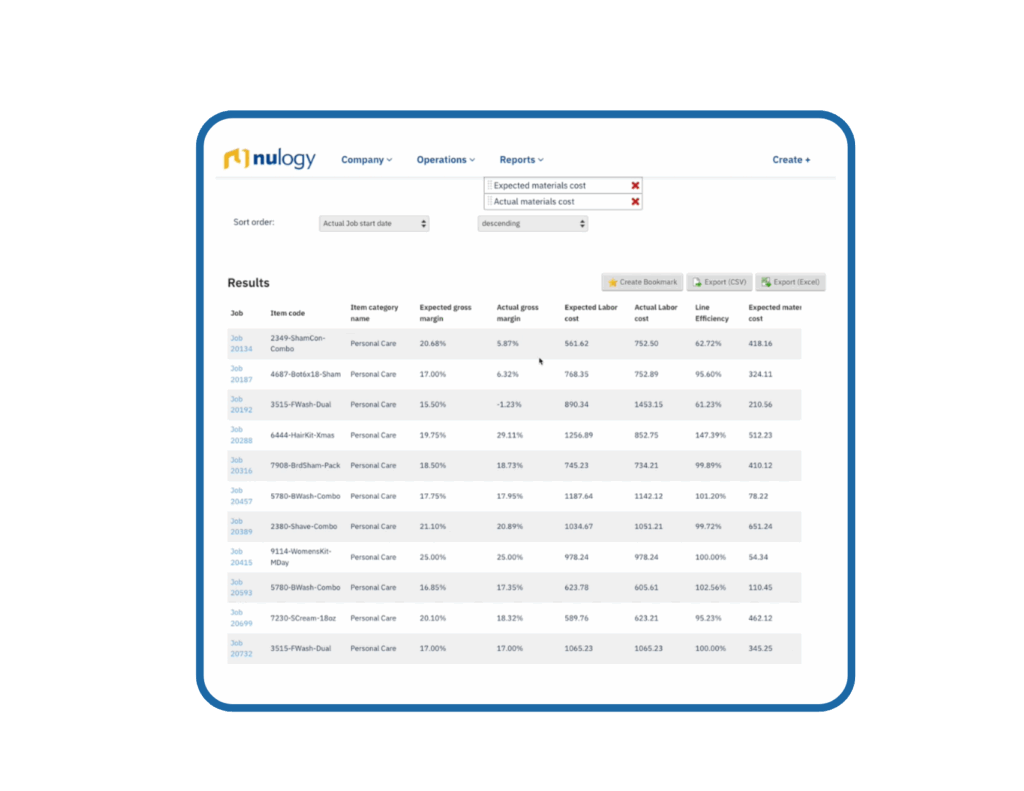

Track Essential KPIs with Customized Reporting

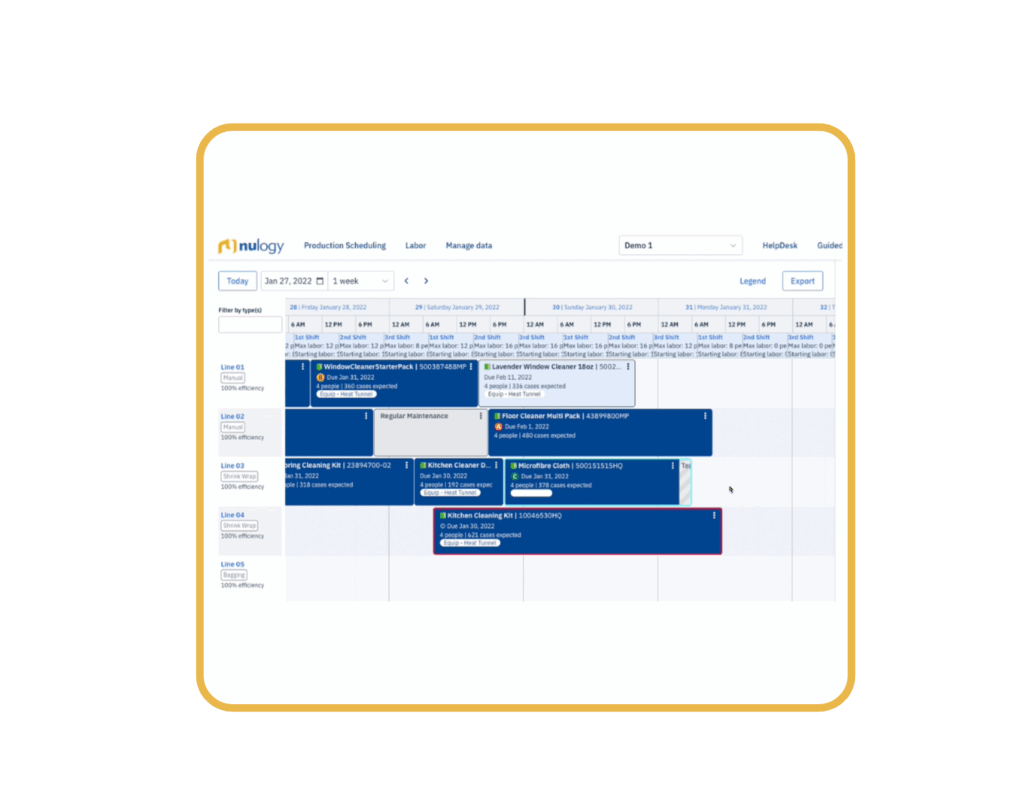

Plan & Schedule Production in One Dashboard

How Nulogy’s Shop Floor Solution Works

Your Complete Digital Toolset for High-Mix, Quick-Turn Manufacturing Environments

Track

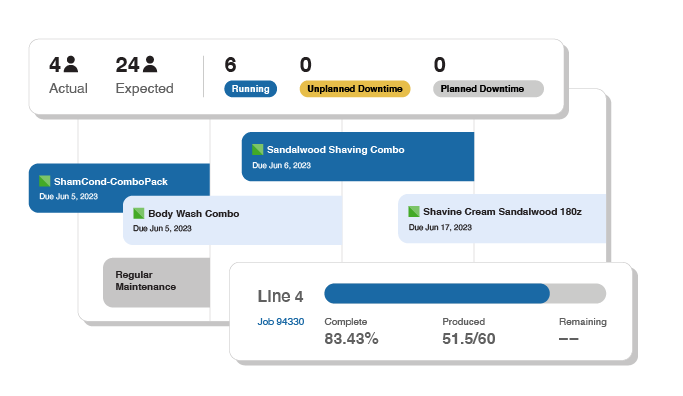

Gain real-time visibility into every job, order, and line — no matter how dynamic.

Ditch the paper and manual processes. Track production, labor, and materials live to make faster, smarter decisions on the floor.

Analyze

Turn shop floor complexity into data-driven clarity.

Identify bottlenecks, downtime, and lost productivity with actionable insights that accelerate improvement in fast-paced operations.

Optimize

Standardize where it counts. Stay flexible where it matters. Digitize critical workflows — from quality checks to inventory movements — to boost efficiency, ensure traceability, and stay audit-ready.

Built for the Pace of High-Mix Production

The Shop Floor Solution is often used by manufacturers running high-mix, quick-turn operations where staying on top of jobs, materials, and labor is a daily challenge. It brings clarity to operations that rely on manual tools but need more visibility to keep production on track.

What Teams Notice First

- Faster access to the status of jobs, changeovers, and line activity

- Less time spent chasing updates or piecing together shift reports

- Fewer surprises during audits, shift transitions, or planning cycles

- Easier to spot downtime trends and track task completion

- A more connected, consistent way to manage day-to-day operations

What Is Your Shop Floor’s Visibility Score?

More Nulogy Success Stories

AmeriPac hits 99.5% inventory accuracy with Nulogy

With Nulogy, AmeriPack is able to track products through the entire supply chain: from receipt to production to reconciliation, into inventory control on the logistics side.

See Case StudyP&G increases receive order productivity by 60%

P&G used Nulogy to digitize their Batch Production Record process which helped them increase efficiency by 40% and receive order accuracy by 40%.

Staffing Synergies scales from 10 to 27 production lines seamlessly

Through Nulogy, Staffing Synergies’ production operations moved into a new facility and grew from 10 to 27 production lines with no impact on customer production expectations.

See Case StudySee How Nulogy Shop Floor Transforms Your Production Operations

Copyright © Nulogy Corporation.

All Rights Reserved.