Challenges Facing Manufacturers Today

Manufacturing businesses are under pressure like never before.

With fewer people, tighter margins, and greater customer demands, manufacturers need every edge they can get to outperform the competition.

As a result, the urgency has never been greater for manufacturers to adopt technology for efficiency and profitability gains. According to a 2024 study of more than 800 manufacturing leaders worldwide, 65% admit that they’re lagging in digital transformation. Further, 82% say their business won’t survive more than three years without a stronger commitment to technology.

The added pressure of labor scarcity in manufacturing also requires companies to do more with fewer people, further pressing the need for the right technology to fulfill jobs and meet deadlines.

Unfortunately, the software market is crowded with vendors that claim to solve the problems on the plant floor and deliver results. So, which manufacturing software do you choose?

The Digital Disconnect Dilemma

The truth is that none of the common software solutions in the manufacturing industry—such as ERP, MOM, or MES—will truly solve the single biggest challenge facing manufacturers today: the Digital Disconnect.

No matter what solutions you use across your business, the problem is that they aren’t talking to each other. Relying on spreadsheets, manual uploads, and other time-consuming workarounds means that the data in every part of your business is siloed and disconnected.

This dilemma translates into painful impacts on every part of your business:

- On the plant floor, machines go down and no one knows why, costing your people valuable time.

- Quality issues slip through during production, leading to scrap, rework, and recalls. Rectifying these issues costs time and money.

- Failed audits and compliance misses add fines, penalties, and damage to your reputation.

- Inventory is either short or overstocked and sitting idle, costing yet more time and money.

- Health and safety (EHS) risks go untracked, exposing your plant to safety incidents.

- Your managers make decisions on old data, leading to lagging responses.

If you’re not solving this problem of Digital Disconnect, all of these costly issues are doomed to repeat themselves and continually add up, siphoning time and money from your business day after day.

In sum: an ERP, MES, or MOM alone is incapable of solving this problem.

Enter: The Manufacturing Operating System

The Manufacturing Operating System (MOS) is a software platform that is specifically built to solve this digital disconnect. The MOS is a single system that builds off your existing solutions to support smarter and more efficient manufacturing, co-packing, and distribution.

Let’s dive a little deeper into what the MOS is and isn’t.

What a Manufacturing Operating System Does

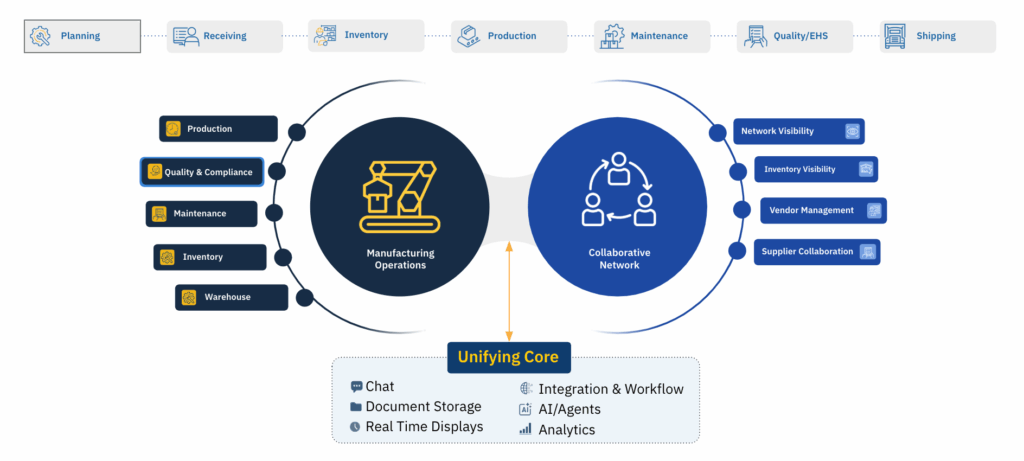

Any proper Manufacturing Operating System should resemble this structure and offer the above features and capabilities across your manufacturing operation.

Manufacturing Operating System Capabilities

The manufacturing operating system offer the following capabilities:

- Production management – Helps you deliver the right product in the right quantity, at the right time with maximum efficiency.

- Quality & Compliance management – Cut hours of paperwork with digital assessments and automate supplier, safety, and quality checks end to end.

- Maintenance management – Proactively maximize uptime and asset life through condition-based maintenance, preventative scheduling, and more.

- Inventory & Material management – Ensure material availability while minimizing waste and inventory costs.

- Warehouse management – Optimize space utilization and instantly manage material movements, storage, and availability.

Further, the MOS provides solutions for collaborating across your vendor and partner network to easily manage capacity, compliance, inventory, and more.

In addition, the Manufacturing Operating System is anchored by a Unifying Core of supporting features and services that drive real-time data, advanced analytics, and AI-driven insights for manufacturers across every site, process, and partner.

And, unlike other vendors that claim to have an end-to-end platform, the MOS provides a modular, purpose-built system that enhances every aspect of the manufacturing process, without needing to rip and replace your existing system or purchase features you don’t need.

What a Manufacturing Operating System Isn’t

The Manufacturing Operating System isn’t just another acronym to substitute for an ERP, MES, or MOM. Purpose-built for manufacturing environments to remedy disconnected systems and lack of data visibility, the MOS stands apart from common software systems in the following ways:

The Manufacturing Operating System isn’t an ERP:

The MOS complements an Enterprise Resource Planning (ERP) system by providing purpose-built automation and data capture throughout the entire manufacturing process.

Many manufacturers have tried to substitute this function with over-customized ERPs, which often result in expensive, time-consuming modifications that are heavily reliant on IT staff or extensive coding experience. With the MOS, over-customized ERPs have become a thing of the past.

The Manufacturing Operating System isn’t an MES:

Manufacturing Execution Systems (MES), as their name indicates, only focus on execution on the plant floor level, and are often connected to machines.

The MOS supplements this function by connecting plant floor sensing data with the rest of your manufacturing data for greater insights, awareness, and responsiveness. With an MOS, you will finally know what’s happening across your business in real time. Better still, all your teams will have access to the same real-time data for faster response to plant floor issues. The MOS gives you the big picture.

The Manufacturing Operating System isn’t an MOM:

Manufacturing Operations Management (MOM) software focuses on scheduling production, tracking materials, logging quality data, and managing maintenance.

To complement the MOM, the MOS acts as the strategic “brain” of your operation, adding structure—in the form of daily management meetings, performance reviews, and standardized improvement routines—and using MOM data as input.

The MOS helps your business set goals, learn, and continuously improve. Without it, you’ll never see the big picture.

Why Choose a Manufacturing Operating System

With an MOS, you don’t have to purchase an expensive software package with features you’ll never use. You only buy what you need for your plant floor now, with additional robust capabilities available when you need them. The MOS is the one system you’ll never outgrow.

By onboarding an MOS, you also don’t need to purchase multiple software packages and spend additional time and money connecting them to each other. The MOS is already connected out of the box, letting you share data for fast, easy insights.

And, by implementing an MOS you’ll never be shackled to expensive IT consultants who don’t understand your business. The MOS is continually updated with new features, backed by services teams who understand the ins and outs of manufacturing operations.

The MOS helps deliver faster implementations and ROI: it is purpose-built for manufacturing environments, by people who have decades of industry experience. Further, the MOS is built for the people running the plant floor, not the IT department. Unlike many of the solutions you’ll encounter in the market, the MOS is easy for your teams to learn and use.

See What Nulogy’s Manufacturing Operating System Offers Today

At Nulogy, our vision is to make life better for the people behind every product: those who plan, produce, and deliver. Our Manufacturing Operating System is the product of that vision, and continually evolves to better solve the challenges that businesses like yours face every day. For hundreds of customers, the MOS has led to greater productivity, efficiency, and customer satisfaction.

Interested to learn more about Nulogy’s MOS? Contact us or request a demo today.