Software

Software

Nulogy’s software is purpose-built to make life easier for the people running manufacturing and packaging operations. By enabling real-time visibility on the factory floor, manufacturers can lower costs, eliminate downtime, and optimize performance.

Nulogy's Manufacturing Operating System

From Machines to Materials - Stay on Track Every Shift

SMART FACTORY Software

Reduce manufacturing downtime and increase throughput.

Monitor production in real time and get alerted immediately as issues happen. With visual dashboards and scoreboards, optimize performance on the factory floor.

Key Benefits:

- Automate Data Collection

- Reduce unplanned downtime

- Improve throughput

- Unlock hidden capacity

SHOP FLOOR Software

Reduce operating costs and improve line performance.

Gain a real-time view of your production, inventory, and labor. Optimize operating costs, production performance, and reporting.

Key Benefits:

- Automate production data

- improve line performance

- Optimize quality processes

- respond faster to disruptions

SUPPLIER COLLABORATION Software

Eliminate redundant spreadsheets and phone calls. Collaborate in real-time.

Connect with customers, vendors, and suppliers in real time to move at the speed of today’s market.

Key Benefits:

- Prevent order delays

- Reduce inventory waste

- Scale up your external network

- Build stronger relationships

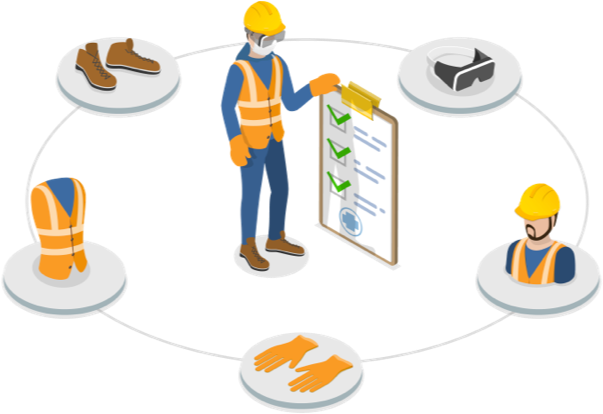

ENVIRONMENTAL HEALTH & SAFETY Software

Safeguard the heath and safety of your frontline workers

Unify your safety programs in a single workspace, from mobile incident capture and corrective actions to asset checks, permits, and sustainability metrics.

Key Benefits:

- Report incidents instantly

- Standardize audits and inspections

- Analyze root causes to prevent future issues

- Securely store documents

QUALITY MANAGEMENT SYSTEM Software

Streamline quality and exceed customer expectations.

Keep quality, suppliers, and manufacturing under control with one connected platform.

Key Benefits:

- Automate data frameworks

- Centralize & control documentation

- Faster review & release

- Reduce quality-related costs

SUPPLIER COMPLIANCE MANAGEMENT Software

Supply chain visibility and compliance, simplified.

A single workspace to onboard suppliers, collect and control documentation, run assessments, manage issues and claimbacks, and monitor performance in real time.

Key Benefits:

- Digital supplier portals

- Document & Certification Management

- Supplier Scoring & Grading

- Centralized Supplier Repositories

Services

Fast, easy onboarding with Nulogy's Services teams

Implementation

With 20+ years of experience in manufacturing and packaging environments, see why Nulogy’s implementation experience is second to none.

Integration

Partner with Nulogy for reliable, consistent, and secure integrations, which support the industry’s most common transactions and systems.

Customer Success

Learn how Nulogy’s customer success teams help you grow and maximize your investment in our software solutions.