Reduce Unplanned Overtime

Produce more with the resources you already have. Optimize labor, budget, and time to fulfill more orders.

Reduce Unplanned Overtime

Produce more with the resources you already have. Optimize labor, budget, and time to fulfill more orders.

Too Much Unplanned Overtime

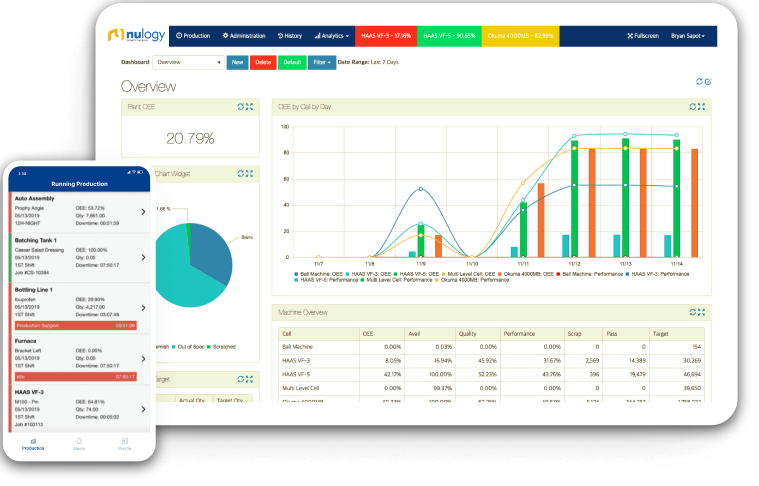

Unplanned overtime causes significantly higher costs, shrinking your bottom line. Whether you’re a contract packager, general manufacturer, or contract manufacturer, Nulogy’s software gives you the real-time visibility needed to truly understand your production performance and issues on the plant floor.

Measuring your plant floor activity, consistently, with Nulogy’s real-time data can help minimize, or even eliminate unplanned overtime.

Getting visibility into the day-to-day activities of the plant will help you eliminate unplanned overtime.

Quickly find and reduce scrap and rework problems. Understand when and why unplanned downtime happens. Know if maintenance is needed.

When you know the details of what’s happening, you’ll be able to stop problems as they happen, before unplanned overtime is needed.

Save Time and Money

By taking advantage of Nulogy’s real-time visibility, you’ll always have the right data needed to create new production schedules, manage inventory levels and allocate labor. Managing costs and improving productivity has never been easier.

See How Nulogy Software Reduces Downtime on the Factory Floor

Watch: Nulogy Customer Success Stories

See how Unette Corporation, LetsGetChecked, and hundreds of other manufacturers and packagers have optimized their production and hit business targets with Nulogy.