Procter & Gamble uses Nulogy to standardize operations across multiple sites, gain visibility into supply chain issues and increase productivity, accuracy, and batch record efficiency.

Founded in 1837, P&G is a consumer products company that supports baby, feminine and family care, as well as beauty, health, and grooming categories.

P&G went live with Nulogy for its first site in 2017. Since then, P&G has implemented the Nulogy Platform at more than a dozen sites, standardizing operations and driving consistent work processes.

Outcomes

Increased receive order productivity & accuracy

P&G used Nulogy to increase their Receive Order productivity by 60% and Receive Order accuracy by 40%.

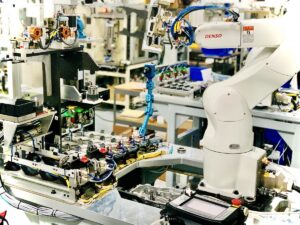

Increased batch production record efficiency by 40%

P&G used Nulogy to digitize their Batch Production Record process which helped them increase efficiency by 40%.

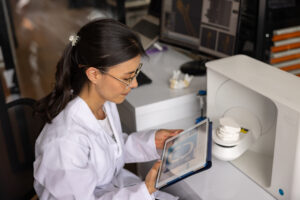

"What I appreciate about Nulogy’s solution is that it’s really intuitive. You don’t feel like you have to have a computer science degree to figure it out."

Bryanna Land

Dayton Mixing Center Processing Engineer, Procter & Gamble