Case Studies

Learn more about the manufacturers and packagers that have achieved success on the plant floor through Nulogy.

Case Studies

Access Nulogy’s library of white papers, webcasts, case studies, and more, featuring insights on supply chain collaboration and external manufacturing.

Prism eLogistics cut recall reporting time by 96% with Nulogy Shop Floor.

Lyons Blow Molding drastically improved production accuracy with Nulogy Smart Factory.

Lincoln Manufacturing saved $100,000 in production costs through Nulogy Smart Factory.

See how Nulogy helped Henderson Group achieve 4x faster audit completion times and 60% reduced reporting time.

See how Nulogy helped McCloskey International eliminate manual processes and reduce rework and waste by 40%.

See how LetsGetChecked improved cycle times by 13% with Nulogy Smart Factory.

Ice Industries tracks inventory with nearly 100% accuracy with Nulogy Smart Factory.

With Smart Factory, H&T Waterbury was able to find small problems throughout the plant that, when corrected, led to significant productivity gains.

Louisiana Fish Fry obtained a 12% OEE improvement within 9 months of deploying Nulogy Smart Factory.

Kinaxia brought Nulogy’s software

to its three sites to optimise their end-to-end contract packing workflow and improve planning, line efficiency and stock control.

Since onboarding Nulogy in 2017, Summit Packaging has increased customer fill rate to 99%, and inventory accuracy to 97%.

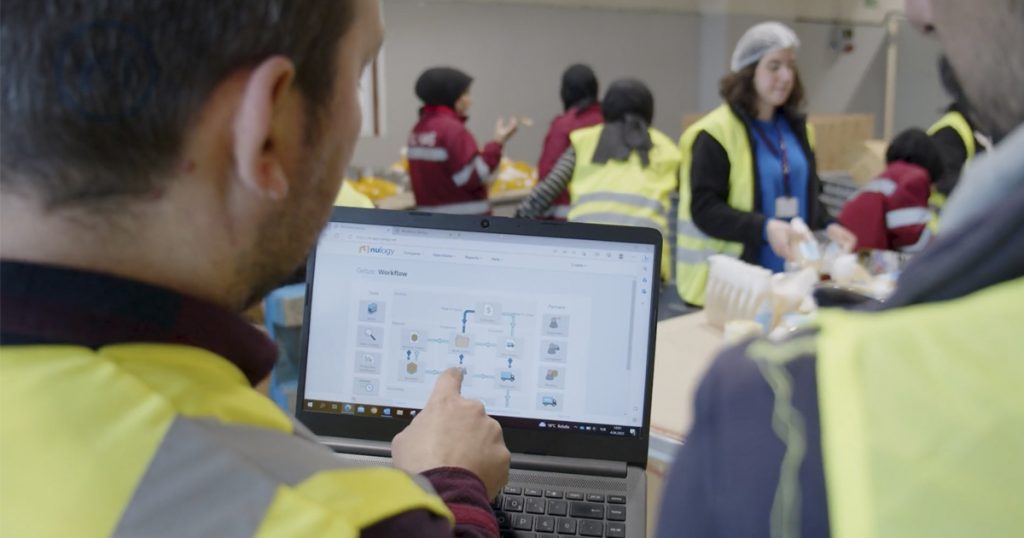

By switching from manual production tracking processes to Nulogy's software, CEVA’s Turkey co-pack sites boosted performance metrics by 10%.

As a long-time Nulogy user, MSI Express has been on the cutting edge of technology adoption in the co-pack industry.

Since implementing Nulogy throughout its facilities in 2020, Capacity has improved plant floor performance as well as long-term business decision-making.

Staffing Synergies implemented Nulogy in a record 30 days, improving production efficiency by 36%+ within 3 months.

Nulogy enabled BCI Packaging to increase revenues by 170%, empowering the co-pack business to better support adults with developmental disabilities.

Unette Corporation leveraged Nulogy to enforce and enhance regulatory compliance procedures, reducing labor costs and improving customer service.

Colgate-Palmolive onboarded Nulogy to improve service levels and collaboration across its Customization Partner network.

Through Nulogy, Kuehne+Nagel's Geel HQ replaced manual processes with data automation—helping provide superior service and added value to its customers.

AmeriPac implemented Nulogy at its co-pack facilities in Texas and Pennsylvania, increasing inventory accurate rates to 99.5%.

Procter & Gamble uses Nulogy to standardize operations across multiple sites, increasing Receive Order productivity by 60% and batch production record efficiency by 40%.