Intended to replace overly complex and expensive traditional solutions, Nulogy Smart Factory is purpose-built for manufacturers needing insight into the factory floor.

Nulogy Smart Factory is purpose-built to fit seamlessly into your existing configurations and workflows. Built by manufacturers for manufacturers, this system was designed from the ground up to accommodate your process, regardless of size, quirks, or idiosyncrasies.

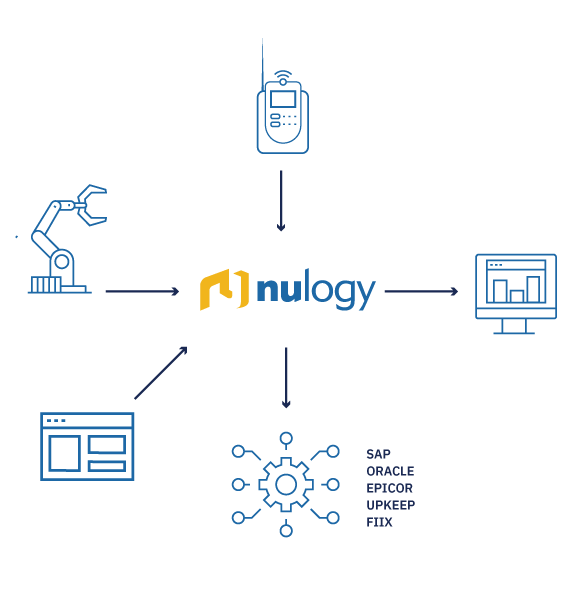

Data is collected from both equipment (PLCs, controllers, photos eyes, wireless nodes) and people. Real-time data is then fed into Smart Factory’s cloud-based platform.

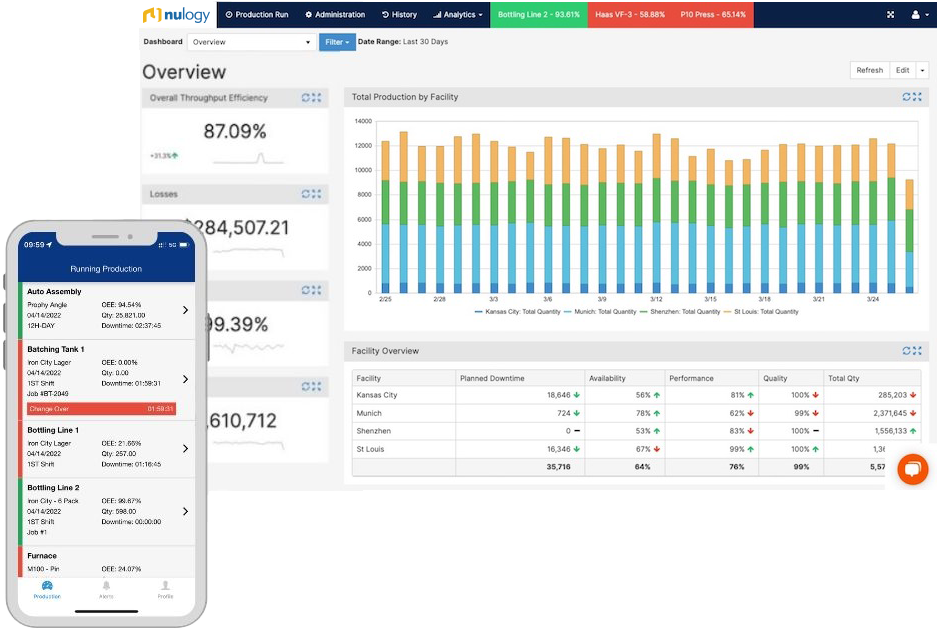

Your data is translated into real time actionable insights, giving you the ability to make better decisions for your operation.

Finally escape from manual spreadsheets and whiteboards.

Quickly get a clear view of your data for better and faster insights.

Automatically collect data from the factory floor, eliminating human error.

See in real-time how your production is running and take steps needed to hit your daily targets.

Know there is an issue before it is becomes a problem. Proactively manage the production floor with mobile and email alerts.

Track and measure Overall Equipment Effectiveness to improve production efficiency.

Smart Factory collects production data easily through wireless sensors, easy-to-use operator screens, or connecting to the existing PLC system. One manufacturing dashboard shows the data you need to know what is happening on the factory floor in real time.

Connectivity is simple and straightforward. When you schedule a call with a member of our team to learn more about manufacturing analytics, we will ask a series of questions about your machines to help determine the best method of connectivity, and determine from there, the next steps that need to be taken. Most of the time, manufacturers already have the equipment necessary to connect to the software. It’s that easy! There are three ways we connect your machines to the software:

We take data security seriously. Nulogy Smart Factory runs our software in a dedicated public cloud (AWS) environment that is as secure as your network security today. All data is encrypted.

Nulogy Smart Factory is designed with the busy manufacturer in mind – the implementation process is quick and straightforward. A Nulogy engineer and account manager will walk you through the entire implementation process. A typical implementation consists of 3 remote training sessions and 1 on-site visit. Small implementations can be completed in 1 day. A full plant implementation typically takes 2 weeks.

Yes! Nulogy Smart Factory provides a managed integration service that connects with most ERP systems. In addition to ERP integration, Nulogy can connect with hundreds of other manufacturing software commonly found in the manufacturing environment.

Nulogy Smart Factory’s pricing structure is tiered based on your factory need to create a cost-effective solution. It is comprised of 3 components:

Yes, we have an award-winning, highly-rated mobile app! The app runs on the Apple IoS and Android operating systems using either tablets or phones.

Want to go deeper? Connect your live production floor data and turn those spreadsheets into real-time dashboards and alerts. Schedule an intro call with a Nulogy Smart Factory expert.