Oral Biotech is a dental technology company based in Albany, OR, specializing in innovative solutions for oral health care. With a focus on research and development, Oral Biotech aims to improve dental

practices and patient outcomes through cutting-edge products and services.

Production Data Helps Oral BioTech Reduce Scrap and Rework

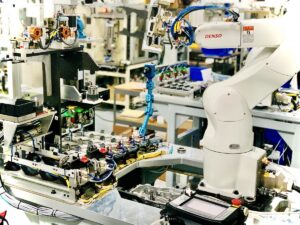

After struggling with an inadequate production monitoring system, Oral Biotech onboarded Nulogy Smart Factory to gain real-time data visibility accessible anywhere, leading to stronger operational efficiency and cost savings due to reduced scrap and rework rates.

The Problem:

Before implementing Nulogy Smart Factory, Oral BioTech was relying heavily on hourly manual reporting that wasn’t counting shortstops during production. Due to this reliance on manual reporting, the company had no way of knowing how much these shortstops were hamstringing their teams’ production efficiency. This blind spot needed to be quickly addressed.

Outcomes:

With Smart Factory, Oral Biotech gained real-time transparency into their manufacturing processes with digital displays throughout the plant, with the additional benefit of freeing its teams to spend more time on value-added tasks.

More specifically, Oral Biotech observed benefits in the following areas:

Greater Real-Time Data Visibility: When the company was recording data manually, no one could remember details or specifics–leading to blind spots in production data. This issue created challenges in data accuracy and plant floor efficiency. Now, with the real-time data provided by Smart Factory, staff are now empowered to get in front of production problems.

Increased Production Effectiveness: The benefits of harnessing Smart Factory became tangible as well. “Before, we were running close to 60% OEE on one of our lines, and now, we’re up close to 80% OEE,” explains John Bowers, Director of Product Management.

Further, production scrap rates have decreased significantly at Oral Biotech. Prior to Smart Factory, scrap rates and rework were between 2% and 3% on average. Now, the manufacturer is down to 1 or 2 units total—a mere fraction of its previous scrap rate.

Accessible & Automated Reporting: Smart Factory was able to integrate with Oral BioTech’s ERP platform, NetSuite.

“Having everything wireless, compared to our previous software which had wires everywhere that had to be plugged in, is huge,” Bowers says.

The plant sensors, combined with Smart Factory’s software, proved to be the winning solution, providing instant data visibility into the plant.