Cycle Time is an essential manufacturing KPI to understand in manufacturing. It is used by ERP and MES systems for scheduling, purchasing and production costing. It is also a critical part of the OEE calculation (use our OEE calculator here). Fortunately, cycle time is easy to calculate and understand.

Cycle time can be measured in several different ways, depending on how production data is tracked and reported. Manufacturing analytics platforms, such as Nulogy, commonly support multiple units of measure to align with different processes and reporting needs. The most frequently used cycle time formats include:

Parts per minute

Minutes per part

Seconds per part

Parts per second

Hours per part

Parts per hour

Selecting the right unit of measure helps ensure cycle time data is easy to interpret, compare, and act on across teams and production lines.

Manufacturers commonly use three terms to describe cycle time. While the names are similar, the exact definitions can vary by organization and production environment.

Theoretical Maximum Machine Cycle – The highest number of parts a machine is capable of producing within a given time period under ideal conditions.

Target Cycle Time – The cycle time required to meet customer demand or supply downstream operations on schedule.

Actual Cycle Time – The real, measured time it takes to produce parts or complete one full production cycle.

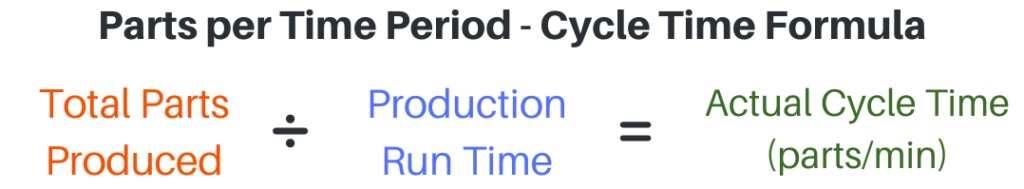

In the sections that follow, we will explain how to calculate cycle time using any of these definitions and how to convert between different units of measure. While there appear to be several cycle time formulas, they all fall into one of two basic categories:

Parts per time period

Time per part

The cycle time calculation is based on two key inputs:

Total Parts Produced – The total number of parts made during the run, including both good parts and scrap.

Production Run Time – The amount of time the machine is actively running while those parts are produced. Planned and unplanned downtime should not be included.

Cycle times often need to be converted into another unit of measure. You can use the list below as a cheat sheet to convert the various formulas into parts per minute.

Minutes per Part

1 / Minutes per Part = Parts per Minute

Seconds per Part

(1 / Seconds per Part) * 60 = Parts per Minute

Parts per Second

Parts per Second * 60 = Parts per Minute

Hours per Part

(1 / Hours per Part) / 60 = Parts per Minute

Parts per Hour

Parts per Hour / 60 = Parts per Minute

Want to go deeper? Connect your live production floor data and turn these calculators into ongoing diagnostics. Schedule an intro call with a Nulogy Smart Factory expert or click the button below to request a demo.