Plastics Manufacturing

Nulogy’s purpose-built software helps plastics manufacturers reduce downtime and overtime, increase availability, improve quality, and ensure on-time delivery.

Plastics Manufacturing

Nulogy’s purpose-built software helps plastics manufacturers reduce downtime and overtime, increase availability, improve quality, and ensure on-time delivery.

Industry Challenges

Every day, plastic manufacturing companies must grapple with a wide range of challenges, including frequent unplanned downtime, inefficient production schedules, and tight deadlines.

Lack of real-time visibility into their complex production processes often result in delays, unscheduled overtime, and trouble consistently hitting production goals and achieving OTIF (On Time In Full) delivery.

Inventory Management

Planning with your external manufacturing partners doesn’t need to be a mess of phone calls, spreadsheets, and email attachments.

Manage inventory, capacity, and planning with your external network on a single platform, with real-time data at your fingertips.

Materials Planning

Proactively plan the procurement WIP and ingredients based on current demand, consumption, inventory levels and more. Incorporate vendor lead times to ensure materials arrive on schedule, avoiding delays in production.

Nulogy’s Materials Planning module gives manufacturers, contract packagers and contract manufacturers the power to purchase, manage, and track the materials needed for all their orders, all in real time.

Production Planning

Ditch the spreadsheets and time wasted manually collecting production floor data.

Optimize your production schedule based on demand, downtime, capacity and configurable constraints. Safely test, iterate, and manage schedules to meet evolving customer and operational requirements. Quickly identify potential conflicts and ensure seamless adjustments to changing production demands.

Increase Operational Efficiency

Hit your production targets in less time and with greater accuracy. See in real-time how your production is running and take steps needed to hit your daily targets. Stop problems as they happen with mobile or email alerts when throughput falls below expected levels.

Scoreboards on the production floor help operators know KPIs and identify the most common causes of downtime.

Manage Health & Safety

Effectively managing Environmental, Health, and Safety (EHS) protocols is critical to running a safe, productive, and reliable manufacturing operation.

Nulogy’s EHS software is designed to help organizations prevent incidents, ensure regulatory compliance, and create a safer workplace through real-time data, automation, and risk-driven decision-making.

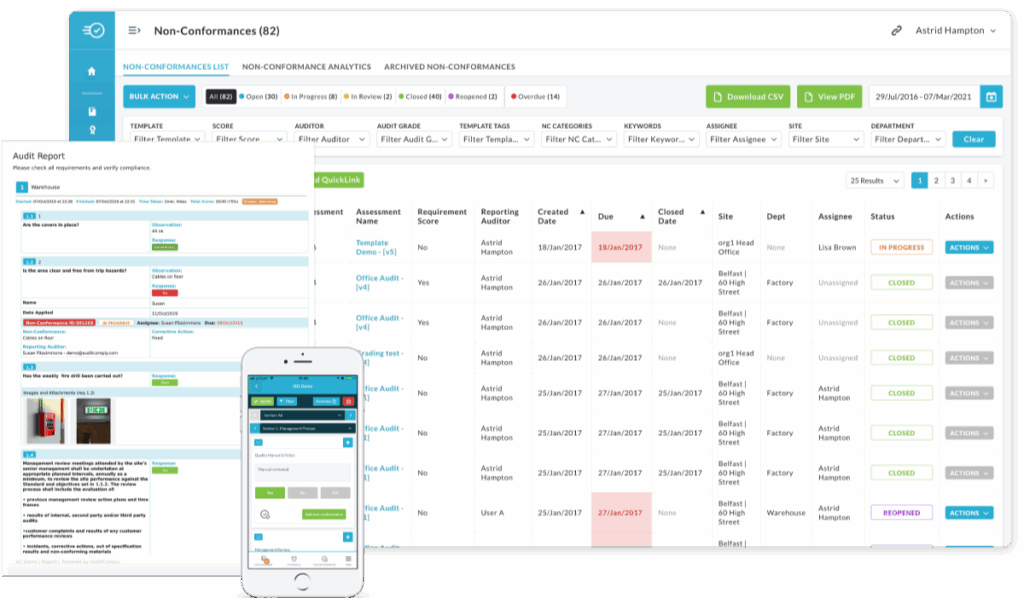

Quality Management

Nulogy Quality Management System (QMS) gives quality managers one workspace to control specs, documents, issues and manage supplier performance. Enforce line checks, capture evidence on any device, and route review and release with e-signature and an audit trail.

Convert issues into CAPA or 8D linked to product and batch while tracking FPY, PPM and closures to cut defects, lower cost of quality, and boost customer satisfaction and compliance.

Supplier Management

Nulogy gives businesses full visibility over their supply chain networks by centralizing supplier data, automating compliance processes, and enhancing collaboration. From onboarding and approvals to risk assessments and performance tracking, Nulogy streamlines every aspect of supplier management.

Enable suppliers to manage tasks, submit required documentation, and respond to compliance requests, all from a single, easy-to-use portal. Improve efficiency by automating assessments, approvals, and corrective actions.

Plastic Manufacturing Benefits

Ditch the Spreadsheets

Finally escape from manual spreadsheets and whiteboards.

Get New Insights & Grow Your Business

Quickly get a clear view of your data for better and faster insights.

Automate Data Collection

Automatically collect data from the factory floor, eliminating human error.

Minimize Overtime

Optimize your production schedule based on demand, downtime, capacity and configurable constraints.

Inventory Control

Track, control, and manage inventory as it moves into production and out again into supplier warehouses.

Reduce Rework

Standardize workflows, identify quality issues early, and get real-time insights to prevent defects and rework.

Purpose-Built for Plastics Manufacturers

Powering speed and efficiency for plastic manufacturing plant floors.

Nulogy’s purpose-built manufacturing software gives you the real-time production visibility needed to monitor performance, machine health, track key metrics, and identify issues before they impact your throughput. With Nulogy, eliminate unexpected downtime, proactively schedule maintenance and minimize disruptions.

By improving visibility across the production floor, Nulogy’s manufacturing software gives plastics manufacturers the power to make smarter decisions, optimize resource allocation, and better align production with demand.

Improve equipment uptime, reduce overtime, and achieve better on-time delivery. Improve profitability and high quality standards by maintaining consistent production performance and meeting delivery deadlines.

ISO 9001 Quality Management

ISO 9001 is the world’s most widely recognized standard for establishing and maintaining a Quality Management System (QMS). It provides a structured framework for organizations to deliver consistent quality, meet regulatory requirements, and enhance customer satisfaction. Adopted across industries such as aviation, construction, automotive, and health sciences, ISO 9001 is often a prerequisite for doing business.

The Foolproof Guide to Increasing OEE

Take these 6 easy steps to increase throughput and efficiency in your manufacturing operation.

Nulogy Manufacturing Success Stories

Learn how plastics manufacturers are using Nulogy to cut costs and reduce manual work while boosting data accuracy.

FAQ

More Questions About Plastics Manufacturing Software?

01 What are the benefits of using injection molding production software?

Gaining real-time production visibility is the first step in optimizing plant floor performance. Manufacturing production monitoring software can provide the functionality needed to collect valuable data for identifying areas for improvement, maximizing resources, and providing ongoing visibility into the factory floor.

- Identify trends

- Track key metrics

- Increase throughput

- Reduce waste

- Decrease downtime

- Integrate with maintenance seamlessly

- Reduce costs

With Nulogy Smart Factory, you can be online within a day and one step closer to a truly efficient plant floor. Begin collecting data on when machines are running and when they aren’t, performance, quality, and availability metrics, OEE, and much more.

02 What’s an example of manufacturing software in action?

There are many benefits in implementing a manufacturing productivity solution as mentioned above. Here are a few examples.

Example 1: Consider a plastics mold that has 2 cavities and can create 2 bottles at a time. With Smart Factory, you can track that the machine cycled, and a machine makes 2 bottles. Note: The number of bottles in this scenario is just an arbitrary number, but the takeaway is that by using software, we can count both molds and parts, and track the cycles.

Example 2: With Nulogy Smart Factory, you will be able to track process data like pressure, vibration, or temperature. If a temperature dips below a recommended level, the software can alert you in real-time.

03 Does your plastic manufacturing software have a mobile app?

Yes, Nulogy has mobile apps available for both Android and iPhone users. Production teams can see availability, performance, and quality metrics, as well as receive alerts of problems on the floor. The app gives manufacturers the ability to respond to real-time issues, immediately, rather than later when it’s too late.

In addition to a mobile app, production teams can receive daily production reports and alerts via email, as well as see performance metrics via various visual management tools like scoreboards, dashboards, and operator screens, all of which provide a complete view into the plant.

04 How can software grow a plastics business?

Manufacturing is in the middle of an evolution. As big data grows in many industries, manufacturers are beginning to implement and use a variety of software designed to create a smart, connected factory. Looking back, the industry has grown tremendously since the first synthetic polymer was invented in 1869. Today, plastics and injection molding manufacturing are worth roughly $96 billion. How does the industry continue to transform and grow? The answer is the use of data to improve and grow the plant.

Look around and you’ll see plastic everywhere – product packaging, medical devices, water bottles, the list is never-ending. Plastic is the third-largest manufacturing industry in the U.S. Yet, on the plant floor where those plastics are produced, most manufacturers have very little visibility into the efficiency of those processes.

With the sheer amount of products containing plastic, there needs to be a way to ensure the plant is running as productive and efficient as possible. The challenge of visibility is solved with manufacturing productivity software. Knowing when machines are up or down, replacing paper and Excel-based reporting, and being able to see and stop problems as they’re happening gives plastics manufacturers the ability to make data-driven decisions.

05 What is the best injection molding production software for businesses?

Implementing real-time manufacturing productivity software on the plant floor has transformed many industries, and plastics are no exception. As we move forward in Industry 4.0, big data and manufacturing analytics have the power to help the plastics industry grow exponentially.

But, how do you know which software to choose and which will ultimately help you grow?

The answer is dependent on your goals as a manufacturer. We can’t tell you which software is going to be the best for your plant because it’s completely dependent on your needs. What do you want to achieve? What improvements do you need to make? Do you have a budget in mind? Will you have a dedicated person or team managing the software? What are your training needs? These are the kinds of questions that need to be pre-determined before selecting a software solution.

If you have questions, you can reach out to our team or schedule a demo. We’re happy to help point you in the right direction.

06 How does Nulogy help plastic manufacturers maintain risk visibility?

Nulogy empowers organizations to proactively manage risks, creating safer, compliant workplaces. With real-time risk identification, assessment, and mitigation, it streamlines Environmental, Health & Safety (EHS) processes, from incident tracking to compliance reporting, ensuring accountability.

Access live data to make informed decisions. Take control of manufacturing challenges on the production floor with real-time visibility, seamless data integration in one dashboard, and automated workflows.