Takt time is a manufacturing term used to describe the rate at which a good needs to be produced to meet customer demand.

It is an important metric because if a manufacturer isn’t able to produce to takt, additional resources such as manpower or money will need to be used to meet demand.

Established as a production management tool by Germany in the 1930s, takt time (“Taktzeit” in German which roughly translates to measure, cycle, or pulse) was designed by engineers as the interval measurement at which aircraft would move to the next step in the production process. Adopted by Toyota in the 1960s, (and translated to takuto taimu in Japanese) takt time has since become a universal manufacturing production term.

Fun Fact: According to the International Group for Lean Manufacturing, some earlier meanings dating back to the 16th century include, “beat triggered by regular contact, clock beat”, then in music “beat indicating the rhythm.”

There is, however, a great debate about the relationship between planned cycle time and takt time.

“How does takt time fit into production and when do you need a takt time calculator, specifically?” The answer is simple. This page is designed to answer and explain:

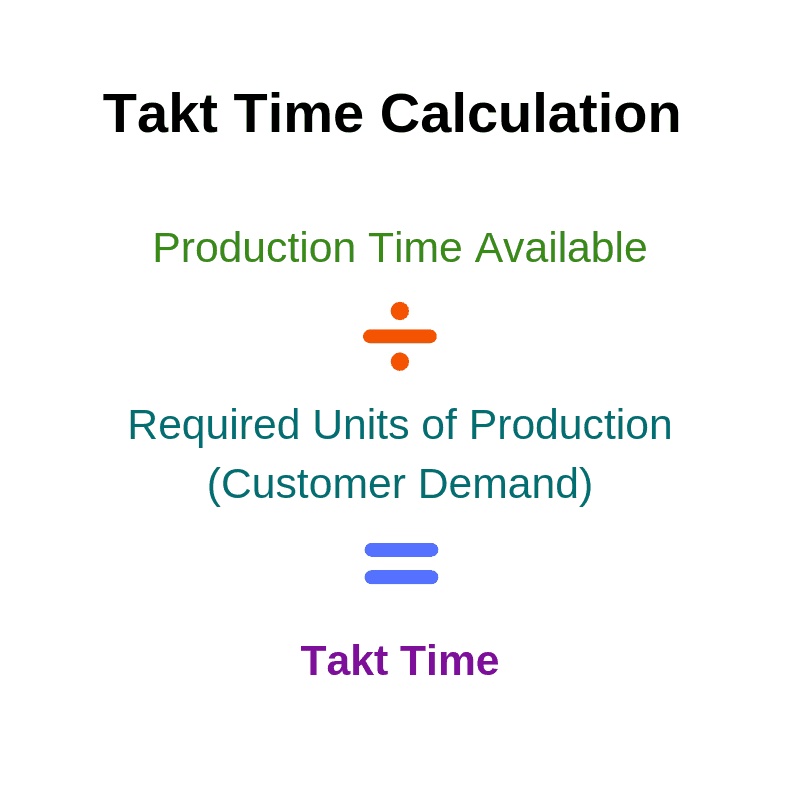

The formula to calculate takt time is production time available divided by the required units of production.

Production Time Available – Production time available is the total amount of time a process can be used to produce parts during a given period. It includes only the time when work can actually be performed and excludes planned interruptions such as lunches, breaks, meetings, or other scheduled downtime.

Required Units of Production (Customer Demand) – Required units of production represent the number of finished units that must be produced within the available production time to meet customer demand. This value is driven by customer orders or downstream requirements and defines how frequently a unit must be completed to stay on pace.

For example, if a customer requires 200 boxes of cereal made in a 10-hour time period, you would calculate:

10 hours of time / 200 boxes of cereal

You would need to produce a box of cereal every 3 minutes. Sounds simple right? It is, but don’t forget that takt time does not account for the amount of manpower needed to produce a box of cereal or breaks such as lunch or meetings. If you know there is an hour lunch scheduled in the 10-hour day, you would need to revise your formula to represent 9 hours of time.

This is where cycle time starts to play a role in determining the number of products produced within a time frame to meet customer demand.

Let’s do another example.

If a process has 28,000 seconds available to complete work per shift, and 800 pieces are required to meet customer demand, how often do you need to complete a piece to meet that demand?

28,000 seconds available time / 800 pieces required = 35 seconds takt time

Using the takt time calculator, you determine that on average, the customer is buying one unit every 35 seconds.

Want to go deeper? Connect your live production floor data and turn these calculators into ongoing diagnostics. Schedule an intro call with a Nulogy Smart Factory expert or click the button below to request a demo.