Metal Stamping & Fabrication

Nulogy’s purpose-built software helps metal stamping and fabrication manufacturers reduce downtime and overtime, manage risk, and ensure on-time delivery.

Metal Stamping & Fabrication

Nulogy’s purpose-built software helps metal stamping and fabrication manufacturers reduce downtime and overtime, manage risk, and ensure on-time delivery.

Industry Challenges

Every day, metal stamping and fabrication manufacturing companies must grapple with a wide range of challenges, including frequent unplanned downtime, inefficient production schedules, and tight deadlines.

Lack of real-time visibility into their complex production processes often result in delays, unscheduled overtime, and trouble consistently hitting production goals and achieving OTIF (On Time In Full) delivery.

Inventory Management

Planning with your external manufacturing partners doesn’t need to be a mess of phone calls, spreadsheets, and email attachments.

Manage inventory, capacity, and planning with your external network on a single platform, with real-time data at your fingertips.

Materials Planning

Proactively plan the procurement WIP and ingredients based on current demand, consumption, inventory levels and more. Incorporate vendor lead times to ensure materials arrive on schedule, avoiding delays in production.

Nulogy’s Materials Planning module gives manufacturers, contract packagers and contract manufacturers the power to purchase, manage, and track the materials needed for all their orders, all in real time.

Production Planning

Ditch the spreadsheets and time wasted manually collecting production floor data.

Optimize your production schedule based on demand, downtime, capacity and configurable constraints. Safely test, iterate, and manage schedules to meet evolving customer and operational requirements. Quickly identify potential conflicts and ensure seamless adjustments to changing production demands.

Increase Operational Efficiency

Hit your production targets in less time and with greater accuracy. See in real-time how your production is running and take steps needed to hit your daily targets. Stop problems as they happen with mobile or email alerts when throughput falls below expected levels.

Scoreboards on the production floor help operators know KPIs and identify the most common causes of downtime.

Manage Health & Safety

Effectively managing Environmental, Health, and Safety (EHS) protocols is critical to running a safe, productive, and reliable manufacturing operation.

Nulogy’s EHS software is designed to help organizations prevent incidents, ensure regulatory compliance, and create a safer workplace through real-time data, automation, and risk-driven decision-making.

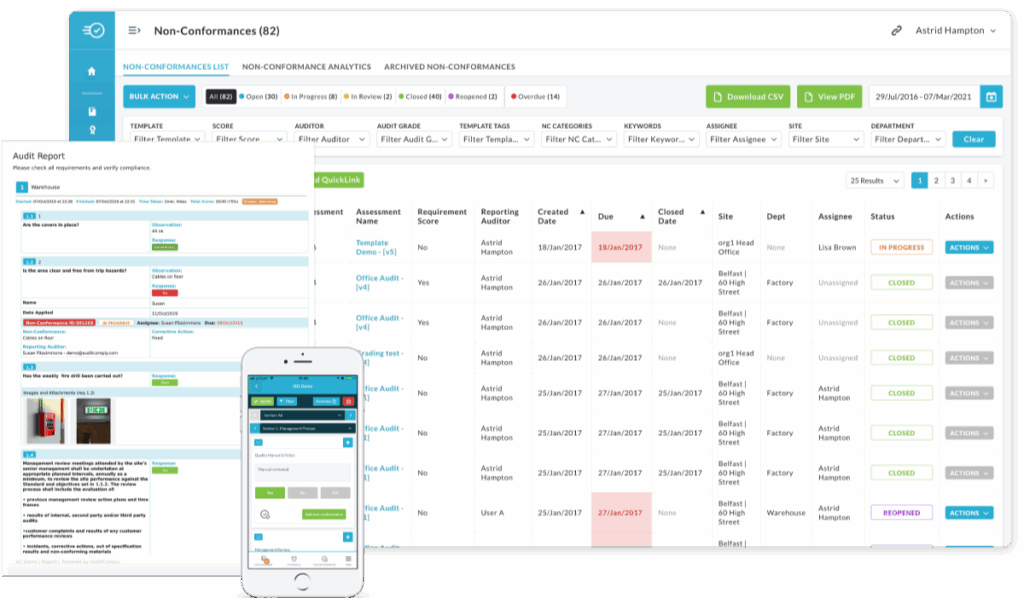

Quality Management

Nulogy Quality Management System (QMS) gives quality managers one workspace to control specs, documents, issues and manage supplier performance. Enforce line checks, capture evidence on any device, and route review and release with e-signature and an audit trail.

Convert issues into CAPA or 8D linked to product and batch while tracking FPY, PPM and closures to cut defects, lower cost of quality, and boost customer satisfaction and compliance.

Supplier Management

Nulogy gives businesses full visibility over their supply chain networks by centralizing supplier data, automating compliance processes, and enhancing collaboration. From onboarding and approvals to risk assessments and performance tracking, Nulogy streamlines every aspect of supplier management.

Enable suppliers to manage tasks, submit required documentation, and respond to compliance requests, all from a single, easy-to-use portal. Improve efficiency by automating assessments, approvals, and corrective actions.

Metal Stamping & Fabrication Benefits

Ditch the Spreadsheets

Finally escape from manual spreadsheets and whiteboards.

Inventory Control

Track, control, and manage inventory as it moves into production and out again into supplier warehouses.

Get New Insights & Grow Your Business

Quickly get a clear view of your data for better and faster insights.

Minimize Overtime

Optimize your production schedule based on demand, downtime, capacity and configurable constraints.

Automate Data Collection

Automatically collect data from the factory floor, eliminating human error.

Reduce Rework

Standardize workflows, identify quality issues early, and get real-time insights to prevent defects and rework.

Purpose-Built for Metal Stamping Manufacturers

Powering speed and efficiency for metal stamping manufacturing plant floors.

Nulogy’s purpose-built manufacturing software gives you the real-time production visibility needed to monitor performance, machine health, track key metrics, and identify issues before they impact your throughput. With Nulogy, eliminate unexpected downtime, proactively schedule maintenance and minimize disruptions.

By improving visibility across the production floor, Nulogy’s manufacturing software gives automotive manufacturers the power to make smarter decisions, optimize resource allocation, and better align production with demand.

Improve equipment uptime, reduce overtime, and achieve better on-time delivery. Improve profitability and ensure customer satisfaction by maintaining consistent production performance and meeting delivery deadlines.

ISO 9001 Quality Management

ISO 9001 is the world’s most widely recognized standard for establishing and maintaining a Quality Management System (QMS). It provides a structured framework for organizations to deliver consistent quality, meet regulatory requirements, and enhance customer satisfaction. Adopted across industries such as aviation, construction, automotive, and health sciences, ISO 9001 is often a prerequisite for doing business.

The Foolproof Guide to Increasing OEE

Take these 6 easy steps to increase throughput and efficiency in your manufacturing operation.

Nulogy Manufacturing Success Stories

Learn how metal stamping & fabrication manufacturers are using Nulogy to reduce downtime, standardize compliance, and eliminate manual work while boosting throughput.

FAQ

More Questions About Metal Stamping Software?

01 What are the benefits of using fabricated metal software?

Manufacturing businesses need production monitoring software to help them understand what’s happening on the floor and make data-driven decisions to improve on-time delivery rates, increase customer satisfaction, and grow revenue.

Eliminate Manual Reporting: Eliminate manual reporting by replacing pen and paper and Excel with automated data collection and real-time dashboards. Instead of waiting for someone to collect, report, and send the data, sometimes days later, you can instantly get insight into production issues in time to correct them.

Know Where You Stand: Traditional planning in an ERP is too rigid, and using Excel is tedious and prone to mistakes. With production monitoring software, manufacturers get flexible production scheduling that enables decision-making on the fly. Make decisions based on labor or customer demands to meet goals and get products out the door.

Increase Capacity: Fabricated metal and metal stamping software give manufacturers the ability to find all of the inefficiencies that cause problems and eliminate them. This leads to increased capacity and being able to produce more with the same amount of resources. Manufacturers will see the capacity to produce quicker and increased profitability.

Achieve Quality Standards: Quality is a crucial metric in the metal forming industry. It’s critical to track and measure quality at all times, yet many manufacturers find this difficult to do without the right software in place. With our software, you can understand the quality of a part from data that is automatically collected, eliminating the need for manual reporting. The data provides insights into problems that are occurring, ultimately helping you improve quality.

02 Does your metal stamping software have a mobile app?

Yes, Nulogy is designed for iOS and Android, giving you real-time insight into the plant, even when remote. The mobile app, in addition to automated manufacturing insights emails, provide configurable alerts. Customize alerts to include only the metrics you care most about – such as unplanned downtime, high scrap rates, or production numbers for each shift.

You can further add visibility into the plant with digital scoreboards on the plant floor, operator screens at every machine, station, or line, and real-time dashboards. See exactly how the plant is performing and if production is ahead or behind schedule. All of these features are designed to give fabricated metal manufacturers and metal stamping manufacturers the ability to make data-driven decisions.

03 How can software grow a metal stamping manufacturing business?

Without real-time data visibility, it’s hard to know what’s happening during production and when product will be delivered. With software designed to tackle these challenges, metal stamping and fabricated metal manufacturers can improve productivity and efficiencies, leading to increased profit margins and customer satisfaction.

Nulogy is designed to meet your needs, allowing you to maintain quality, increase capacity, eliminate manual reporting, and flexibly plan your production.

04 What is the best software for metal stamping and fabricated metal businesses?

The best software for metal stamping and metal fabricating manufacturers is the one that is going to help achieve your goals.

It’s important that you to make an informed decision about the needs of your plant. What do you want to achieve by implementing production monitoring software? This is the question you’re going to need to answer before moving forward with any company.

When you’ve decided on goals you want to achieve, the next step is determining how that software vendor will help you achieve those goals. What is their business philosophy? What do they promise to solve? What is their pricing? Does it fit within your budget? Will the software help you grow over time? There are a lot of questions you’re going to need to ask before making a decision. But, this isn’t a decision to be made lightly. Whichever vendor you choose needs to be able to help you achieve your goals. If they aren’t going to be able to do that, it might not be the right fit.

05 How does Nulogy help metal stamping and fabrication manufacturers maintain risk visibility?

Nulogy empowers organizations to proactively manage risks, creating safer, compliant workplaces. With real-time risk identification, assessment, and mitigation, it streamlines Environmental, Health & Safety (EHS) processes, from incident tracking to compliance reporting, ensuring accountability.

Access live data to make informed decisions. Take control of manufacturing challenges on the production floor with real-time visibility, seamless data integration in one dashboard, and automated workflows.