What do supply chains and music have in common? More than you might think. For my keynote presentation at Nulogy xChange 2023, which was hosted in Nashville (aka Music City), I wanted to use music to illustrate the value and need for collaboration in consumer brand supply chain networks.

Let’s take a look at some surprising parallels between these two seemingly unrelated practices. Some shared principles between the two include:

- Connect with people

- Synchronize with partners

- Anticipate variability

Connect with people

By itself, a single musical note is barely recognizable or noteworthy. But, string together a series of notes and ultimately you can create a song. Hum a tune or play a track, and it will generate a response from listeners.

If you think of the visual parallels, a composition in music is a series of notes. Similarly, supply chains are traditionally depicted as a literal chain: a sequence of connected nodes, assets, or individuals that are connected together. And, whether it be colleagues, partners, suppliers and customers, we are personally connecting with people. Connections matter.

Just like the single music note, one business alone cannot create or bring a final product to market. When working together with other partners, however, supply chain providers create some of the most well-known and impactful products that are used and consumed by people everyday.

In both music and supply chain, the whole is greater than the sum of its parts.

Ultimately, visibility between partners is needed to connect the dots. In today’s complex global supply chains, visibility is crucial to effectively manage risks and make informed decisions. Collaborative supply chains leverage technology and data sharing to provide real-time visibility into inventory levels, transportation routes, demand patterns, and other critical information. This enables supply chain partners to proactively identify and mitigate risks, optimize inventory levels, and respond to changing customer demands.

Without visibility, it is very difficult to communicate, let alone collaborate, innovate, or build trust. Visibility enables the connections that make true collaboration happen.

Synchronize with partners

Now that we’ve established that the whole is greater than the sum of its parts, let’s talk about the importance of synchronization. Regardless of your musicality or abilities, we can all empathize with that dreaded feeling of singing off-key, or dancing with two left feet.

Synchronization matters in music, regardless of whether you’re the performer or the audience. Everyone is partaking in the same experience – everyone feels the highs of perfect orchestration and the lows of missed beats.

In the world of supply chain, hundreds, if not thousands of businesses, suppliers, and brands all around the world are trying to navigate a climate rife with disruption. A myriad of professionals—supply chain planning, procurement, and IT, among others—are working together around the clock with a shared goal: to continually deliver the everyday products we all need to sustain our quality of life.

And, just as the different layers that comprise a song—such as the baseline, melody and vocals—create a harmonious result, trading partners across multiple echelons in the supply chain need to work together in concert.

The challenge, of course, is synchronization: when multiple parties across the globe are collaborating to plan, execute, and deliver multitudes of product shipments every day, is everyone on the same page? Can their systems keep up with the real-time disruptions, demand shifts, and shortages that have become part and parcel of today’s market?

In other words: are all the above parties reading off the same song sheet? Do they know who is leading the dance? Are they equipped with the tools needed to harmonize together? If not, what are the repercussions of being offbeat and off-key?

In the supply chain, like in music, staying synchronized is the objective. If you have one party out of sync, that creates waste and confusion, and the bullwhip effect can exacerbate the issue. Conversely, investments made in synchronizing partners and processes within complex supply chain networks leads to more accurate data and insights, faster response, and ultimately, more agile supply chains.

Anticipate variability

Another key component to harmonizing music is managing variability. For example, consider a DJ that is playing at a wedding or a party. When he or she is mixing two different songs, the transition must be seamless. Regardless of whether the beat transitions to a lower or higher tempo, there is a shift in variability.

Good DJs can smoothly navigate these shifts in variability, keeping the party going for everyone. Bad DJs, on the other hand, can ruin the vibe and cause disruption and confusion in the audience.

In the world of supply chain, variability stems from a wide range of potential events: natural disasters, shortages of goods, pandemics, or even a ship stuck in a canal. These events can result in delays in production, transportation disruptions, or even damage to inventory or facilities.

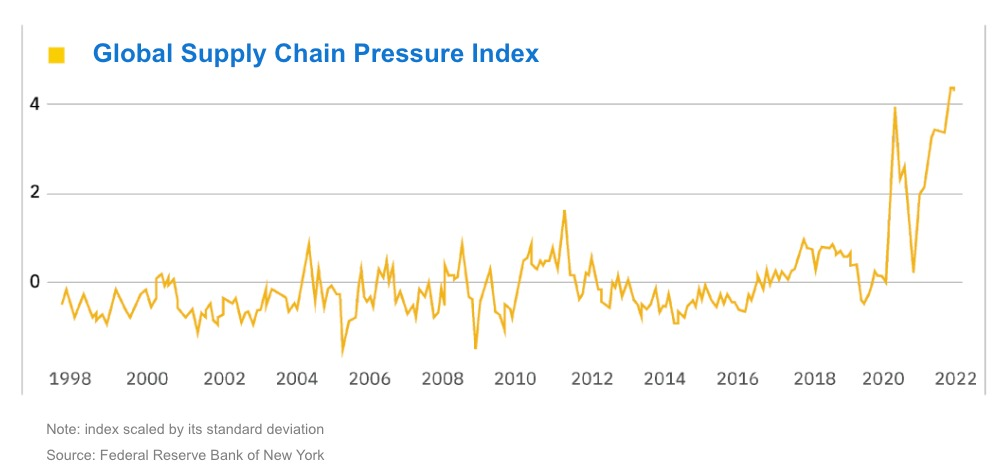

And that variability is here to stay. According to the Federal Reserve Bank of New York’s Global Supply Chain Pressure Index, disruptions are actually increasing over time.

A more responsive and agile design to supply chains are required. The ability to respond to changes in production and adapt to demand changes is critical.

Brands are also increasingly weighing the ease of doing business including transparency, trust, agility, adaptiveness and communications. This emphasis is underscored further by real-time visibility and cross-company collaboration.

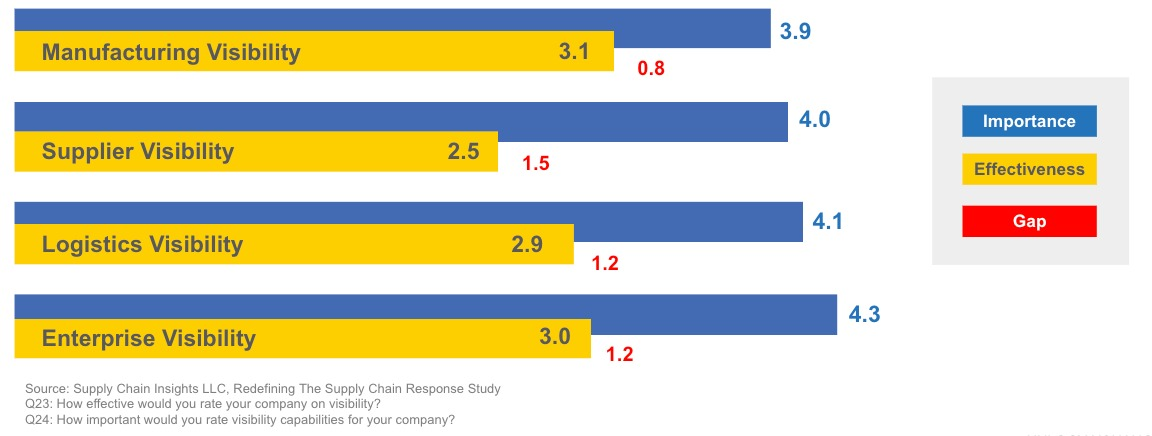

In a recent analysis done by Supply Chain Insights, the gap to improve in the areas of Manufacturing Visibility, Supplier Visibility, Logistics Visibility and Enterprise Visibility is immense.

Across all four elements of visibility, there are massive opportunities–with the gap being most pronounced in Supplier Visibility, including Contract Manufacturing, Packaging & 3PLs. That gap can only be closed through collaboration.

How can businesses take advantage of this gap in visibility? By enabling the data visibility needed in their systems to collaborate more effectively with their customers and trading partners. And only a multi-enterprise collaboration platform such as Nulogy can shine a light into the black box of your network to work together seamlessly.

Fine-tune your collaborative capabilities today

In summary:

Value your connections: Make sure you have the visibility you need to work together effectively both within your organization as well as beyond its four walls.

Stay in sync with them: Use that visibility to collaborate effectively with trading partners to minimize waste and drive efficiency and accuracy.

Collaborate to manage variability: Variability and disruption is here to stay. Anticipate changes in tempo and ensure you and your trading partners can manage them when they come.

Supply chain collaboration is not just a buzzword, but a critical enabler of business success in today’s dynamic business environment. It fosters innovation, enhances visibility, improves sustainability, and strengthens relationships. It’s time for businesses to embrace a collaborative mindset and work together to unlock the full potential of their supply chains.