Software

Smart Factory

Software

Smart Factory

Stop losing time.

Start winning the day.

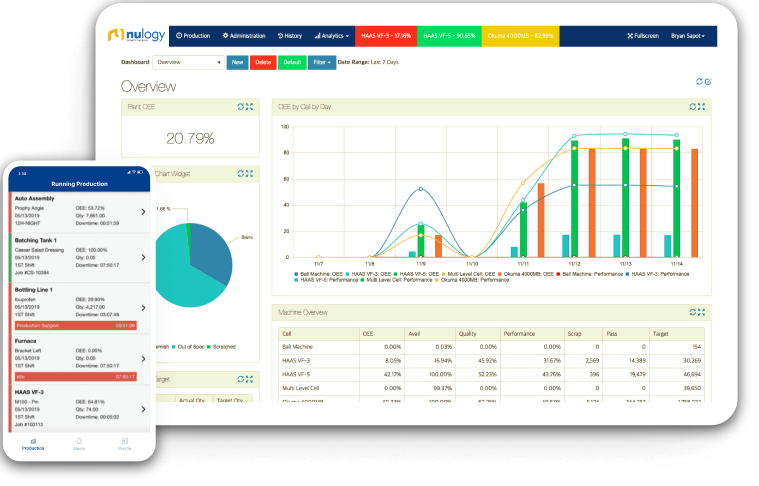

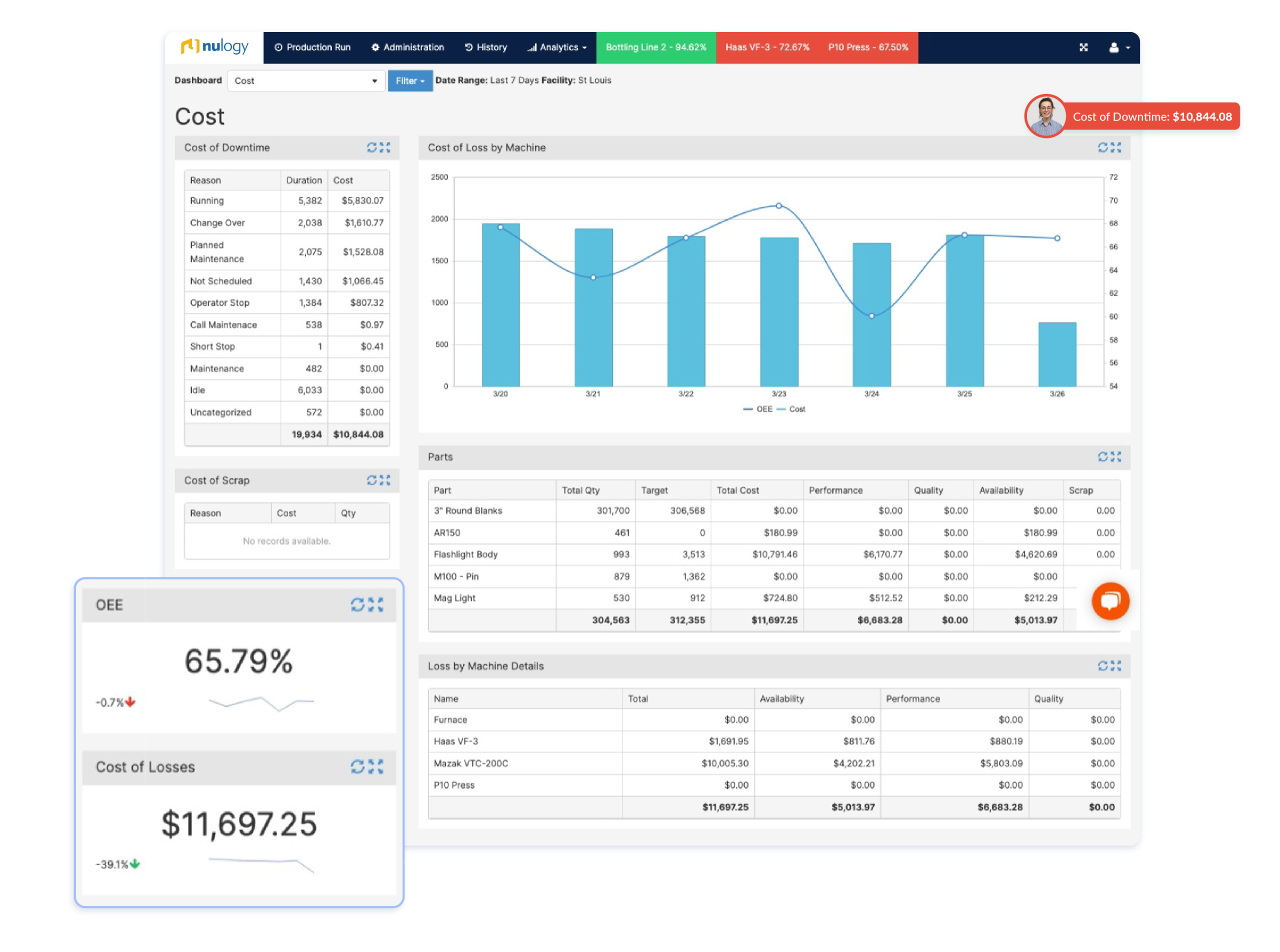

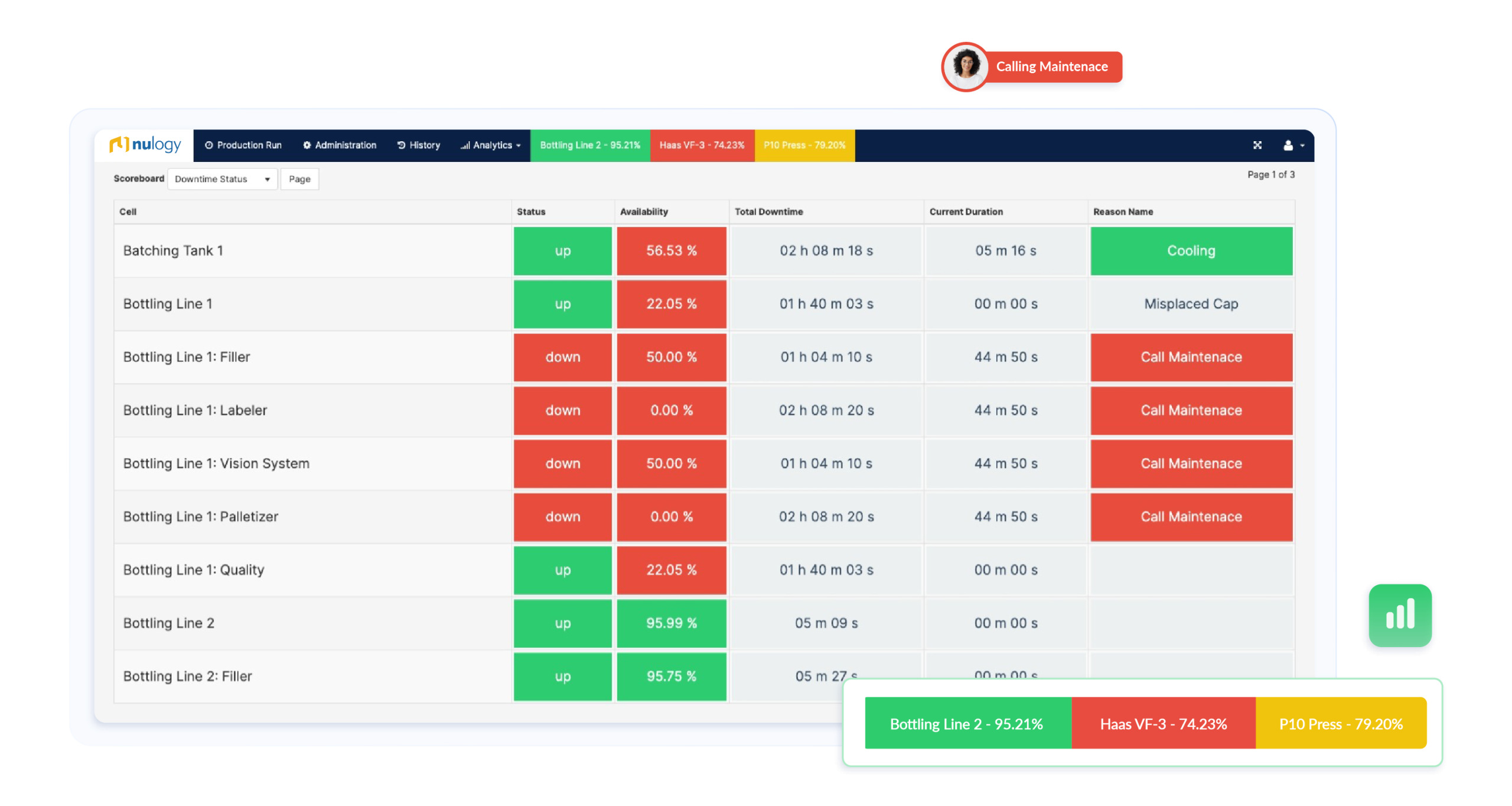

Real-time visibility for today’s manufacturing plants

Gain real-time visibility on the plant floor to reduce downtime, increase OEE, and hit production goals.

Nulogy Smart Factory is the industry-leading production monitoring software for manufacturers. Purpose-built for your plant, Smart Factory is easy to use, quick to implement, and is the one system you’ll never outgrow.

Industries We Serve

Understand and optimize your plant floor

We help manufacturers in the automotive industry solve their plant floor issues and deliver with excellence.

Manage quality control processes with ease

Nulogy’s software makes food & beverage QC processes a breeze. Sleep easy thanks to Nulogy’s digital traceability and recall capabilities.

Our purpose-built software helps metal fabrication manufacturers reduce downtime, increase availability, and ensure on-time delivery.

Nulogy’s software provides real-time visibility into contract packaging and manufacturing production processes and quality assurance.

Gain the real-time production visibility needed to monitor plastics manufacturing performance, machine health, and track key metrics.

See how Nulogy helps contract manufacturers, contract packagers, and raw and material suppliers work smarter and faster.

Your machines and lines keep suffering unplanned downtime and you don’t know why.

With Smart Factory

Automatically collect data from any machine, old or new, getting real-time visibility into downtime causes.

You’re spending too much time manually producing reports, rather than actually solving problems.

With Smart Factory

Get automatic reporting by end of shift, end of day or end of week, straight to your inbox.

You’re not hitting your daily or weekly production goals, and constantly feeling let down.

With Smart Factory

Customizable, easy-to-use dashboards give you the information you need to run the plant on a day-to-day basis.

Your customers are unhappy due to missed deadlines or late deliveries.

With Smart Factory

Integrate your schedule and know if you will hit your due dates before its a problem.

Your data is inaccurate and unreliable due to manual entry and human error.

With Smart Factory

Automatically collect data from every machine on the factory floor, eliminating human error.

Proven Results

Smart Factory has driven success for manufacturers:

Smart Factory Digital Assessment

If a manufacturer has world-class OEE scores across their plant floor, they’re extracting every ounce of potential from their equipment while minimizing losses from unplanned downtime, speed or quality issues. It’s the ultimate competitive weapon for managing costs and operating efficiently.

This 20 question assessment will take about five minutes and show you:

- What level of digital transformation your factory floor is ready for

- Potential OEE increase working with a production monitoring system

- Next steps for optimization

How Smart Factory Works

Watch Smart Factory in Action

Nulogy Smart Factory is purpsoe-built to fit seamlessly into your existing configurations and workflows. Built by manufacturers for manufacturers, this system was designed from the ground up to accommodate your process, regardless of size, quirks, or idiosyncrasies.

The Foolproof Guide to Increasing OEE

Take these 6 easy steps to increase throughput and efficiency in your manufacturing operation.