In July, I had the honour of leading a panel discussion titled The Benefits of Digitalisation at the 2024 BCMPA Conference in Nottingham, UK. Joined by industry leaders Richard Pinkerton, Confectionery Procurement Business Partner at Nestlè UK; Thomas Verbeke, Global Coman Excellence Manager at Danone; and Steve Tarrant, Chairman at Glowcroft Contract Packing, we explored how digitalisation is reshaping FMCG external supply chains by enabling faster and more accurate data flow between partners for stronger collaboration and shared success.

For anyone invested in the future of FMCG manufacturing supply chains, the discussion offered a wealth of insights on how digital tools are not just enhancing operational efficiency, but also fostering deeper collaboration and trust amongst the partners that work together across the value chain—such as contract packers, contract manufacturers and value-added logistics providers. Here is a summary of the most thought-provoking themes from the session.

The Role of Data in Fostering Collaboration

For Richard Pinkerton at Nestlè UK, the speed and quality of data is critical to enabling and validating trust between parties in the value chain—especially in a market rife with change. Richard stressed that the ability to trace order information within a single system fosters transparency in partner relationships while allowing for a brand to maintain full visibility over every aspect of their planning and procurement. He shared, “[When issues arise,] we need full visibility very quickly [so that we can] assess actions we need to take in order to protect our consumers.” In this way, both FMCG brands and their external partners play a critical role in safeguarding the brand.

When issues arise, we need full visibility very quickly so that we can assess actions we need to take in order to protect our consumers.

-Richard Pinkerton, Confectionery Procurement Business Partner, Nestlè UK

Subsequently, what kinds of Industry 4.0 technology allows for this type of multi-enterprise collaboration and data flow? Thomas Verbeke at Danone explained how important it is to seek out platforms that encourage digital standardisation within the industry such that dashboards with critical metrics—such as key performance indicator (KPI) data and enterprise resource planning (ERP) system data—are shared on a single system. Doing so breaks down data silos inherent in traditional systems, which allows for enhanced business insights and optimisation opportunities. In particular, solutions such as Nulogy’s Supplier Collaboration Solution are purpose-built to enable real-time collaboration between external manufacturing partners.

In addition, more sophisticated systems can allow for more granular data insights across the value chain: “We will one day also request our contract manufacturers to provide systems where you have your bill of materials broken down, which you can then put an emission factor behind it, put other quality KPIs behind it, and put finance KPIs behind it,” explained Richard.

There needs to be transparency, and we need to be as accountable as possible.

Steve Tarrant, Chairman, Glowcroft Contract Packing

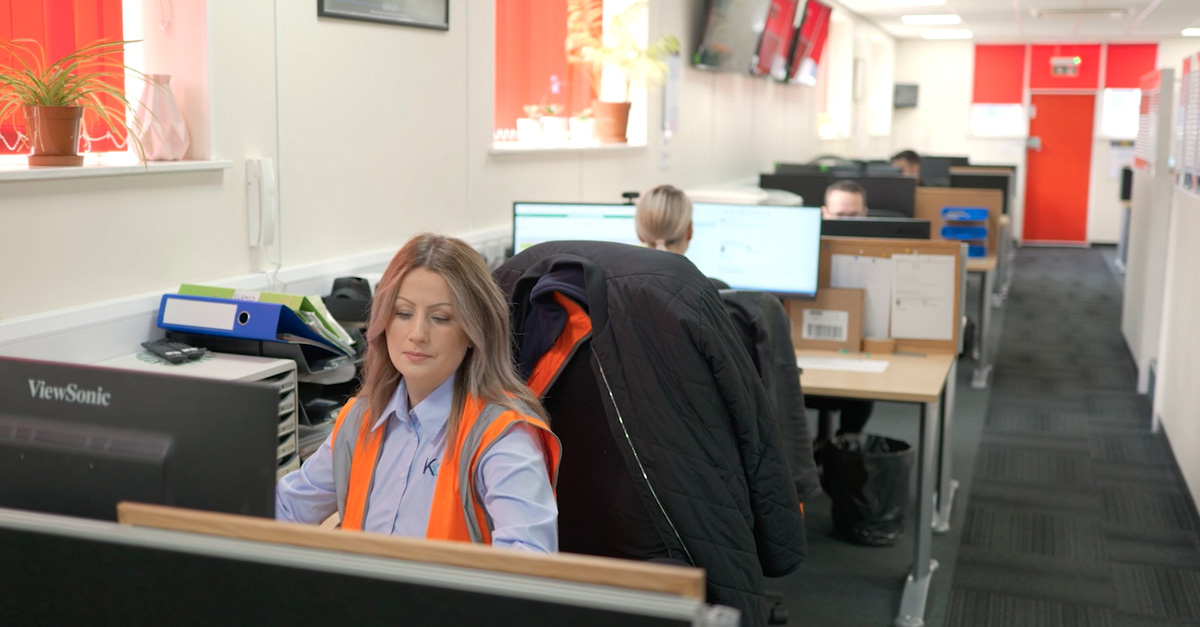

Representing the perspective of the contract packer, Steve Tarrant at Glowcroft echoed the need for—and value of—data transparency across the network: “We all work for brand owners, and their expectations of contract packers is that we can’t keep [our processes] as a dark art anymore, where people send us goods and we magically do something in a factory. There needs to be transparency, and we need to be as accountable as possible.”

Change doesn’t always come easily, but the panelists agreed that digitalisation is the standard of the future. That said, what is the best way to implement it into business with the least amount of disruption in the day-to-day functions of staff?

Guiding Your Team Through Digital Transformation

One aspect of digitalisation that breeds uncertainty—and perhaps even fear—amongst manufacturing leaders is the challenge of cultural transformation, where a positive environment must be created to ensure teams embrace progress instead of resisting it. How does an organisation tackle this challenge and unite their teams with a common objective?

Steve Tarrant cautioned against rushing into a new digitalisation project. “We decided that in order to keep up with the market sector and customer requirements, we needed to change. Nulogy was a long-term investment—so we had to put careful thought into it just as we would with any new piece of equipment,” he said.

Everyone had a role to play within the onboarding process and, when people realised that the new solutions were permanent and would eventually make their own roles easier, they naturally became more open to it over time. A slower approach to transition gives teams time to become familiar with new technologies and may result in a smoother transformation process overall.

Thomas added that it’s up to industry leaders to discover which innovators will lead the pack in digital standardisation, and that companies such as Nulogy have the pressure and privilege to continue growing and adapting as the industry’s needs outgrow spreadsheets and conventional tools.

The Importance of Data Accuracy Within the Manufacturing Industry

You may be surprised to learn that 81% of brand owners and contract manufacturers rely on email, spreadsheets and phone calls to manage complex workflows. In our fast-paced environment, reliable access to high-quality, accurate data is critical, yet difficult to achieve with outdated tools.

As Steve explained, the stakes are high and organisations can quickly lose control of their operations without the right data. Even worse, key stakeholders may begin losing confidence in your business. Leaders must have access to the right information immediately so that they can weigh options quickly and make informed decisions on the spot to benefit not only their stakeholders, but also their teams and reputations.

A prominent takeaway for me is that digital transformation can liberate people to produce higher value work. It can help them upskill and improve their working lives as opposed to the opposite, and that’s something we should all pursue for ourselves and those around us.

Thank you to Thomas, Richard, and Steve for taking the time to share their insights and experience, and to the BCMPA for hosting the panel session and running a fantastic conference. Nulogy was proud to sponsor this important annual event, and I look forward to attending next year.

Interested in tuning into the full conversation? Watch the panel discussion on-demand now.